What is 75/25 welding gas or 25-75 welding gas?

75/25 Welding gas is a binary gas mixture of 75% Argon + 25% Carbon dioxide (CO2). 75/25 Welding gas is the most widely used gas mix for welding carbon steel, mild steel, and low alloy steel.

The Shielding gases are classified according to AWS A5.32 or ISO 14175 standards. The classification symbol for 75/25 Welding gas as per AWS A5.32 is ‘SG-AC-25‘. The classification symbol for 75/25 Welding gas as per ISO 14175 is ‘M22‘.

SG-AC-25 has completely replaced the use of pure CO2 in GMAW & FCAW welding. 75/25 Welding gas can be used for all position welding. 75/25 Welding gas gives short circuit or globular transfer modes in welding depending on the welding current & voltage range.

Shielding gases of TIG MIG and FCAW welding of stainless steel, duplex steel

Permitted tolerances in 75/25 welding gas

75/25 Welding gas or 75 argon 25 carbon dioxide gas has 75% argon (Major component) and the remaining 25% Carbon dioxide (minor component). But in actuality, it is not practical to have the gases within this close tolerances.

Hence, AWS A5.32- Table 4 permitted a variation in the gas mixture which is ±10% relative to the minor percentage component. So, in the case of 75-25 Welding gas, the minor component range is 25%. For this the allowed permissible tolerance is given below:

Argon75%- CO2 25% (Welding gas classification: SG-AC-25)

25 X 0.1 = 2.5%

So, the minimum CO2 percentage shall be: 25 − 2.5 = 22.5%

The maximum CO2 percentage shall be: 25 + 2.5= 27.5%

Permissible tolerances on Carbon dioxide in 75-25 Welding Gas: Argon with 22.5 to 27.5% CO2.

What is SG-AC-25 (Argon shield) Welding Gas?

SG-AC-25 is the gas classification for 75-25 welding gas according to the AWS A5.32 specification. This gas contains 75% Argon + 25% Carbon dioxide (CO2).

- SG: means Shielding Gas

- AC: means gases where ‘A’ means Argon and ‘C’ for Carbon dioxide.

- 25: 25 is the percentage of the minor component. Here it is CO2.

What can you weld with 75/25 welding gas?

75/25 welding gas is a binary gas mixture of 75% argon and 25% carbon dioxide (CO2). Compared to pure carbon dioxide, 75/25 welding gas gives improved weld bead profile, reduced welding spatters, and good arc stability.

75/25 welding gas is mainly used for welding mild steel, carbon steel, and low alloy steel only. 75/25 welding gas can not be used for welding stainless steel because it will result in high oxidation of stainless steel due to the presence of oxygen produced by CO2 dissociation in the welding arc.

Mode of metal transfer in 75/25 welding gas

The mode of metal transfer when using 75/25 welding gas is either short circuit metal transfer or Globular transfer. With low current & voltage, usually less than 150 amperes, the mode is a short circuit.

Click to learn about Metal Transfer Mode in GMAW, FCAW & SMAW

With the increase in the welding current the mode changes to globular metal transfer. Globular metal transfer mode provides a higher weld deposition rate compared to short circuit but it is not suitable for thin sheet welding.

Welding Electrode/ Filler wire/ Filler metal Selection Chart

What is 75% argon -25% CO2 used for?

75/25 welding gas is mainly used for welding unalloyed mild steel, carbon steel, and low alloy steel only. 75/25 welding gas can not be used for welding stainless steel because it will result in high oxidation of stainless steel due to the presence of oxygen produced by CO2 dissociation in the welding arc.

75/25 Welding gas is used for GMAW and FCAW welding processes with solid and flux-cored welding wires. Short arc welding with 75/25 Welding gas is used for thin sheet and gap bridging applications.

Can you use 75 argon 25 CO2 to TIG weld?

Honest answer- No. You should not or I say, You must not use 75/25 welding gas with TIG welding. The reason is that the CO2 gas will destroy your tungsten at a rapid rate due to oxidation.

You may think that it is working fine and welding is taking place but in actuality, you are oxidizing your precious tungsten rod. So my advice– DON’T DO IT unless it’s an emergency and you have no other option.

Can you weld aluminum with 75 argon 25 CO2?

Straight forward answer- No. CO2 being an oxidizing welding gas is not suitable for aluminum welding and 75/25 welding gas has sufficient CO2 to make a welding mess.

Also, CO2 during dissociation in the welding arc will create oxygen which is highly dangerous for aluminum welding. You will get a lot of porosity inside the weld (that you can see either in radiography or a weld macro). Although from the outside weld might look like a normal weld with little oxidation.

How long does a MIG or TIG welding gas cylinder/ bottle last?

Many times we need to calculate or estimate the welding shielding or purging gas. We need to know how long a cylinder will run if I do a continuous weld. This can also help for costing purposes or to calculate the required gas for a specific project.

So, how you can calculate and find how long a gas cylinder/ bottle will last in welding?

To find out you have to see the gas flow rate which is the amount of gas taken out from the cylinder during welding. The unit of gas flow rate is CFH or cubic feet per hour. Generally, in TIG & MIG welding we use a gas flow rate of 15 to 50 CFH (Cubic feet/ hour).

Lighter shielding gases such as helium or a mixture of helium and when welding in outdoor conditions requires a higher gas flow rate. But ideally, 20 -30 CFH is good for most of the welding operations & conditions. Welding of steel requires less gas flow compared to aluminum welding.

Now, to find out how long a Welding gas cylinder last, you need to have below pre hand data:

- Total volume of gas in the cylinder in Cubic feet (cf).

- Gas flow rate in CFH (Cubic feet/hour)

Based on this, the welding gas cylinder can be used for:

Let us consider an example of a 50 cubic feet gas cylinder that has been used with a flow rate of 25 CFH.

Then; gas cylinder running hours = 50/25 = 2 Hours

75/25 welding gas cylinder (Bottle) sizes

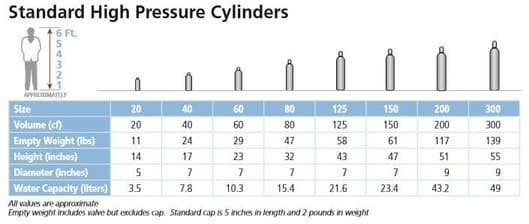

The gas suppliers makes gas cylinders to standard sizes of 250, 300 and 350 CF. Smaller sizes of 20CF , 40CF, 80 CF & 125CF gas bottles are available for hobby welders & DIY uses.

Due to higher gas capacity, longer running duration & less time for filling & handling, larger gas bottles are cheaper compared to smaller one. The standard sizes, volume, empty weight, diameter and height of welding gas cylinders are given in the below table.

75/25 welding gas regulator?

Which regulator you should use for 75/25 welding gas or mixture of argon + CO2 welding gas?

Which type of regular is best for 75/25 welding gas or mixture of argon + CO2 welding gas? All these are obvious questions many people asks. The major component of 75/25 welding gas is argon.

So, it is recommended to use argon gas regulator for 75/25 welding gas. You will find many different brands in the market for regulators. Below are the recommended 75/25 welding gas regulators that offers best quality at best rate:

- Check the best price for 75/25 welding gas regulator

- Forney Regulator best price for 75/25 welding gas regulator

- Victor Make Regulator best price for 75/25 welding gas regulator