8018 welding rod

An 8018 welding rod is a low-hydrogen electrode that is used for Stick Welding (shielded metal arc welding).

It is a versatile electrode that can be used on a variety of metals, including carbon steel, low-alloy steel, and cast steel. The 8018 welding rod is available in a variety of sizes, from 3/32″ to 3/16″.

8018 Welding rod has a higher tensile strength of 80Ksi compared to 7018 welding rod. The 8018 welding electrode is a popular choice for many welders because it produces a high-quality weld.

It is also easy to use and can be used on a variety of metals. The 8018 welding rod is available in a variety of sizes, so it can be used for both small and large projects.

E8018 electrode specification

An E8018 electrode is a low-alloy, iron powder electrode that produces high-quality, radiographic welds.

It is most commonly used for welding low-carbon steels and is ideal for applications where strength and ductility are required.

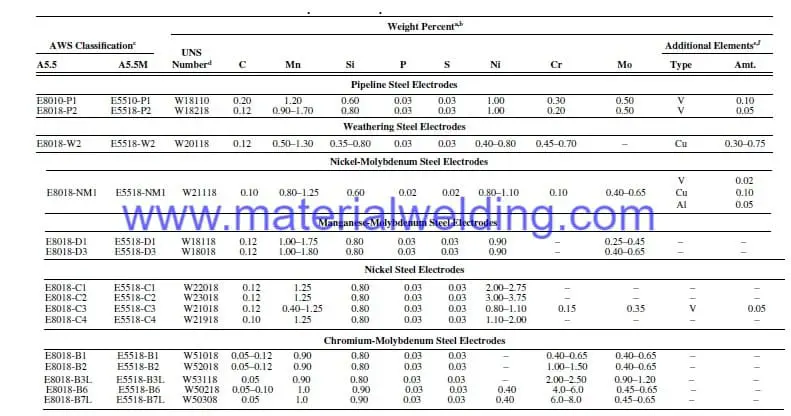

E8018 Welding Electrode specification is AWS A5.5. AWS A5.5 is a low alloy steel stick welding rod specification.

It covers welding electrodes for high strength low alloy steel such as Cr-Mo, Nickel steel, Nickel-Moly, military electrodes, Pipeline welding rods and Weathering steel welding rods.

8018 welding rod Types

8018 Welding rods are available in various strength and alloy compositions ranging from normal low alloy steel to military grade steel materials.

The most commonly used E8018 Welding electrode types are:

- E8018-B2, E8018-B3, E8018-B6, E8018-B7, E8018-B8: For Cr-Moly Steel welding electrodes

- E8018C1, E8018C2, E8018C3, E8018C4: Nickel Steel welding electrodes

- E8018NM1: Nickel-Moly Steel welding electrodes

- E8018-D2, E8018-D3: Manganese-Moly welding electrodes

- E8010-P1, E8018-P2: Pipe steel welding electrodes

- E8018-W2: Weathering steel welding electrodes

All these above E8018 type welding rods are covered in AWS A5.5 Specification. This specification provides chemical and mechanical properties of these electrodes.

8018 welding rod chemical composition

8018 welding rod chemical composition depends on the types of complete welding rod classification.

E8018-BX types welding rods contains Cr-Moly alloying elements, E8018-CX types welding rods contains mainly nickel alloying.

E8018NM1has Nickel and Moly as main alloying elements. You can find the complete chemical compositions of these welding electrodes in the below table.

8018 welding rod meaning

The 8018 welding rod is a low-hydrogen electrode that is most commonly used for welding mild steel and low-alloy steels.

The “80” in the name refers to the minimum tensile strength in Ksi that the rod can achieve.

The “1 & 8” designates that the rod can be used in all welding positions, and it is a low hydrogen rod useable with AC & DCEP polarity.

This makes the 8018 welding electrode an excellent choice for beginners and those who are welding in difficult positions.

8018 welding rod uses

The 8018 welding electrode is a versatile tool that can be used for many different purposes. E8018 welding rod is available in different variants allowing it to use for various applications such as:

- For Cr-Moly Steel alloy welding such as P11, P22, P5 & P9

- For Nickel Steel alloy welding

- Nickel-Moly Steel alloy welding

- Manganese-Moly alloy welding

- Pipeline welding applications

- Weathering steel welding such as Corten steel welding

The 8018 welding electrode is a versatile tool that can be used for many different purposes.

It is made of a high quality metal that is resistant to brittle failure and can withstand high temperatures. This makes it ideal for use in welding applications.

8018 welding rod amperage

If you’re a welder, then you know that 8018 welding rod amperage is an important factor to consider when welding. But what exactly is the right amperage for 8018 welding rod, and how do you find it?

The answer isn’t always simple, as there are a few factors that can affect the amperage needed for 8018 welding rod.

But in general, you’ll want to use an amperage that’s between 70 and 110 amps for 1/8 inch rod. Higher diameter rods requires higher welding amperage.

Of course, the best way to determine the perfect amperage for your project is to experiment a bit and see what gives you the best results.

But if you’re just starting out, using an amperage in the middle of the range is a good place to start.

To find the perfect amperage for your 8018 welding rod, it’s important to experiment a little bit.

Start by using an amperage that’s on the lower end of the range and then increase it until you find the sweet spot.

E8018 Rod Welding Positions

An E8018 electrode is a low hydrogen coated electrode that is best suited for use in horizontal, flat, or uphill welding positions.

This electrode can also be used in all positions. The E8018 electrode has a low carbon content which makes it ideal for many applications.

This electrode also has a high deposition rate, making it ideal for use in welding applications where speed is a factor.

7018 vs 8018 Welding Rod

There are a few key differences between 7018 and 8018 welding rod. E7018 is for mainly carbon steel welding while E8018 rods are used for welding of various types of low alloy steel, low alloy steel to carbon steel welding applications as listed above.

The main differences between 7018 vs. 8018 welding rod are listed in below table.

| E7018 | E8018 |

|

|---|---|---|

| AWS Specification | AWS A 5.1 | AWS A 5.5 |

| AWS Classification | E7018 | E8018-B2 & others |

| Coating type | Low Hydrogen Iron Powder | Low hydrogen iron powder |

| Tensile Strength | 70 Ksi | 80 Ksi |

| Yield Strength | 57 Ksi | 67 Ksi |

| Polarity | AC, DCEP | AC, DCEP |

| Chemistry | Carbon steel rod | Low alloy steel rod |

Similar Posts:

- E8018-B2 electrode specification and meaning: Everything you need to know

- E7018 vs E7018-1 vs E6013 vs E7016 vs E6011 all other Welding Rod Explained

- Complete Guide for Welding Rod Types, Meaning and Uses

- How to Choose the Right Stick Welding Electrode and Rod Type

Material Welding is run by highly experienced welding engineers, welding trainers & ASNT NDT Level III bloggers.

We strive to provide most accurate and practical knowledge in welding, metallurgy, NDT and Engineering domains.