When it comes to understanding the world of architecture, engineering, and construction, acronyms can often feel overwhelming. One such acronym is AESS, which stands for Architecturally Exposed Structural Steel. In this blog post, we’ll break down the various AESS categories in simple terms, helping you grasp their significance.

What is AESS?

AESS refers to structural steel elements that are designed not just for strength and stability but also for aesthetic appeal. These elements are often visible in a building’s design, meaning they serve a dual purpose: supporting the structure while also enhancing its visual appeal.

Why Are AESS Categories Important?

AESS categories help architects and engineers communicate the level of finish and detailing required for exposed steel elements. This ensures that everyone involved in a project understands how these elements should look and how much work is needed to achieve the desired appearance.

Standards for AESS Categories

Architecturally Exposed Structural Steel (AESS) is governed by various standards that ensure both aesthetic quality and structural integrity. Two prominent standards in this field are AS 5131 and guidelines from the American Institute of Steel Construction (AISC).

The AESS Categories Explained

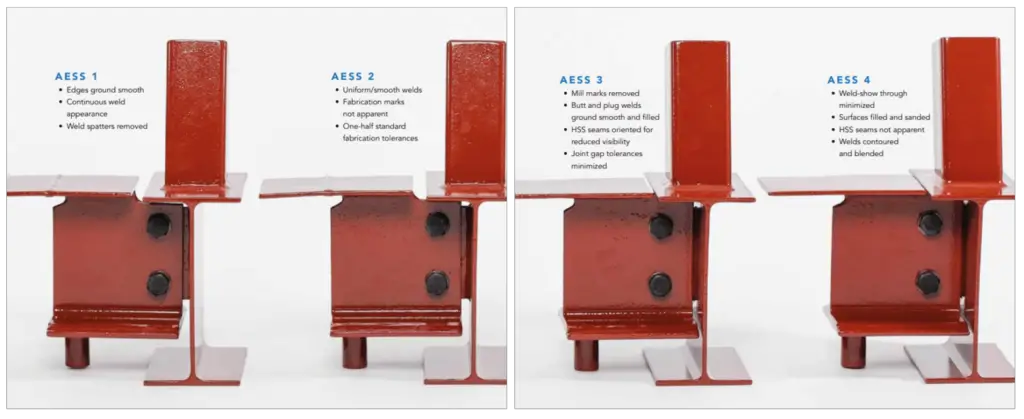

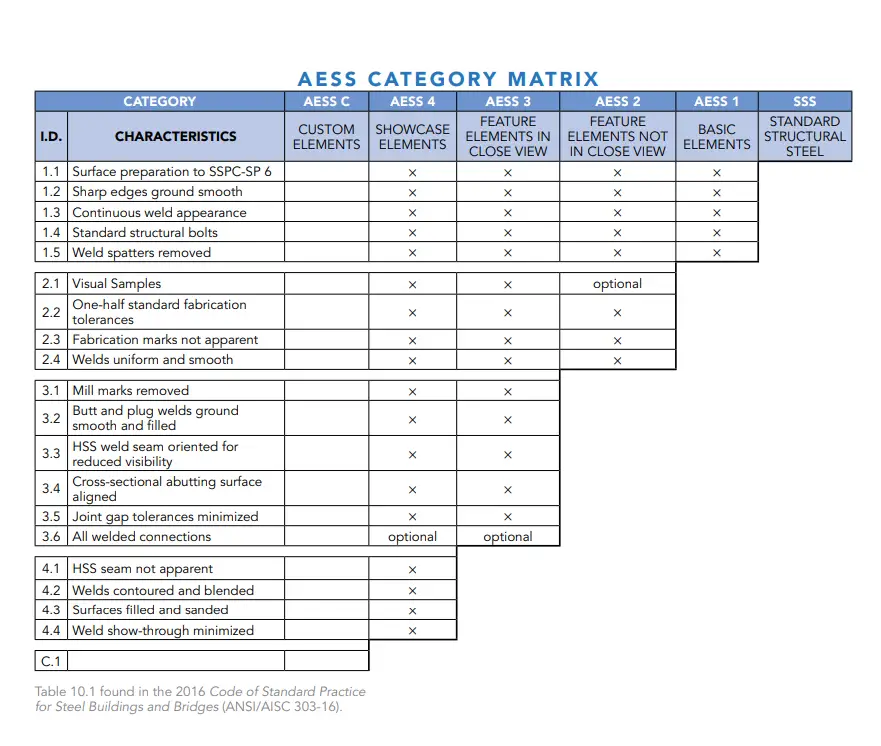

There are five distinct categories that define the level of Architecturally Exposed Structural Steel (AESS) for a project as defined in AS 5131 Standard:

- AESS 1: Basic Elements

- AESS 2: Feature Elements Not in Close View

- AESS 3: Feature Elements in Close View

- AESS 4: Showcase Elements

- AESS C: Custom Elements

As the category number increases, the requirements tend to be more demanding, which usually leads to higher costs. AESS C, representing Custom Elements, may require fewer finishing levels than the Basic Elements in AESS 1, or it might exceed the standards set for Showcase Elements in AESS 4. When opting for AESS C, it’s crucial to include detailed information in the drawings and specifications to clearly convey the design intent.

1. AESS 1: Basic Appearance

- Description: This is the simplest level of architectural finish.

- Features: The steel is cleaned and painted but may have visible welds and connections.

- Use Cases: Common in utilitarian buildings where aesthetics are not the primary concern.

2. AESS 2: Intermediate Appearance

- Description: This category requires a higher level of finishing than AESS 1.

- Features: Steel surfaces are smoother, and welds are generally more refined. Some connections may be concealed.

- Use Cases: Often found in public spaces, like lobbies or galleries, where a better visual impression is desired.

3. AESS 3: Advanced Appearance

- Description: This level is all about aesthetics and detail.

- Features: Steel elements are meticulously finished. Welds are ground down, and all connections are concealed or made to look seamless.

- Use Cases: Used in high-profile buildings, museums, or areas where the steel is a focal point.

4. AESS 4: Exceptional Appearance

- Description: The highest level of architectural finish.

- Features: This category demands impeccable detailing, often with custom finishes. Every aspect of the steel is designed to be visually stunning.

- Use Cases: Seen in landmark structures or iconic buildings where the steel is a key design element.

Dr. Sandeep Kumar

Hi, I'm Dr. Sandeep Kumar. I am a passionate Welding & Material Expert with a Ph.D. and M.Sc. in Welding Engineering. As an International Welding Engineer (IWE), I bridge the gap between academic research and practical industrial application. My goal is to share high-level knowledge on metallurgy, welding technical knowledge, and engineering best practices to help professionals and students succeed in the field.