Fillet Weld

In the field of heavy machinery, shipbuilding, structures and construction, and other complex welding fabrications consist of numerous welded joints.

Among them, fillet welding is more economical than groove welding, so it is widely used for corner, T, lap joint welding. This is because fillet welding simplifies end machining and fit-up preparation.

Fillet weld is relatively simple to execute and provides a strong weld joint for joining two members for T-Joint, Lap joint and corner weld joints.

Parts of a Fillet Weld

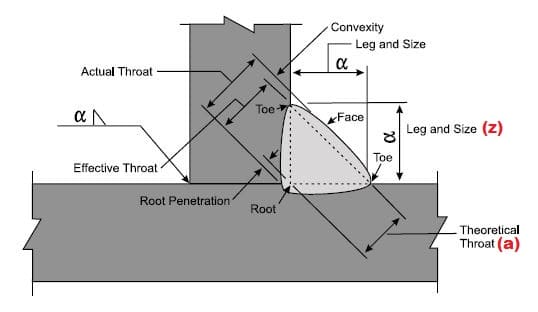

A fillet weld has following main parts that make it up are listed below and shown in the figure:

- Leg Length (z),

- Throat size (a),

- Weld face,

- Weld root,

- Weld Toe,

- Convexity,

- Concavity.

Leg Length & Throat Size of a Fillet Weld

By design, the strength of the fillet weld is based on the:

- Theoretical throat= design throat thickness (T) and effective area (w) of the weld (T x W), as shown in below Figure.

The fillet weld leg (L in figure above) determines the size of the fillet weld. The fillet weld size is measured as the length of the angular field of the largest right triangle with the cross-sectional area that can be drawn inside the fillet weld.

How to Calculate Throat Size of Fillet Weld?

A Fillet weld leg length size (L, also denoted by z) determines the theoretical throat of the weld. You can use fillet weld size formula to calculate the Fillet Weld size.

As throat size is difficult to measure in a fillet weld. By measuring the leg length- L (z) and using the empirical formula given below derived by fillet weld geometry, you can find out the throat size (a) of a fillet weld.

- Throat size (a) = Leg Length (z) x 0.7 or

- Leg Length (z) – Throat size (a) x 1.41

Minimum Fillet Weld Size

The fillet welding size must be sufficient to withstand the allowable weight, but the weld size must not be excessive to reduce welding deformation and cost.

The AWS D 1.1 (Structural Welding Code ― Steel) code, table 7.7 (given below) specifies the minimum fillet weld size for each base material thickness. (e.g., 6-mm size for thickness over 1.5” (12mm) up to 4/4” (20 mm).

Measuring Fillet Weld Size

Measurements of Fillet Welds is carried out to check:

- Leg Length of a Fillet Weld,

- Throat size of a Fillet Weld,

- Weld inspection to check excessive convexity, concavity and asymmetry.

Measurement of Fillet weld Leg Size

Measuring Leg Length of Convex & Concave Fillet weld

Measurement of Fillet weld Throat Size

Measuring Skewed Fillet Weld Size

For measuring Skewed Fillet weld, you need special gauge as shown in the below picture. This gauge is also known as Skewed Fillet weld Gauge.

Using Skewed Fillet Weld Gauge (Courtesy: GAL Gauges)

Fillet Weld measurement using Bridge Cam Gauge

Bridge Cam Gauge can be used to measure fillet weld:

- Throat Size (a),

- Leg Length (z).

Refer below figure for placement of bridgecam gauge for fillet weld throat and leg length measurement.

Measuring Fillet Weld Convexity, Concavity and Overlap

Fillet Weld Size in ASME B31.1

ASME B31.1 code gives information about fillet weld size. The figure below shows the fillet weld sizes as required by ASME B31.1.

Material Welding is run by highly experienced welding engineers, welding trainers & ASNT NDT Level III bloggers.

We strive to provide most accurate and practical knowledge in welding, metallurgy, NDT and Engineering domains.