How does Stick Weld work?

To start the Stick Weld operation, the welder fixes the bare, contact end of a flux-coated stick welding rod into the holder and strikes an arc by touching or scratching the workpiece with the arc-striking end of the electrode and then withdrawing it slightly to maintain a short arc.

The heat of the welding arc gradually consumes the electrode and converts it into weld metal and slag.

The welder manually guides the stick welding electrode and controls its direction and arc travel speed.

He also maintains a steady arc length by feeding the electrode skillfully into the workpiece. The welder ends the welding operation by withdrawing the electrode suddenly and thereby breaking the stick welding arc.

Stick Weld Amperage Chart & Setting

Setting correct weld Amperage in Stick Welding is very important to have a good quality weld with a nice finish.

There are Welders Tips for amperage setting in stick welding based on electrode diameters, welding position, welding joint type, rod coating type, and material thickness.

Stick Welding (SMAW) Amperage Chart for E6010, E6011, E6013, E7015, E7018 & E7024 for diameters 3/32-inch, 1/8-inch, 5/32-inch, and 3/16-inch stick welding rod diameters are given in the below table.

This Stick Welding Amperage Chart provided recommended welding amperage for different rod diameters.

Thumb Rule for Stick Welding Amperage: 40 X stick welding rod diameter in mm

Stick Welding (SMAW) Amperage requirements based on Rod Coating:

- Electrode with thin coating: Require low amperage e.g. E6013 stick welding rod

- Electrode with medium coating: Normal amperage e.g. E7015 stick welding rod.

- Electrode with very thick coating: High amperage e.g. E7024 stick welding rod.

Based on Material thickness, Stick Welding amperage can be selected:

- Thin material ( 1/16” to 5.16”): Low amperage for stick Welding

- Normal thickness material (>5/16” <1/2”): Normal amperage for stick Welding

- Thick material (More than 1/2 inches): High amperage for stick Welding

Stick Welding Tips & Techniques

A stick welder skill in performing a good quality weld involves:

- Striking the arc

- Maintaining a short and steady arc length

- Making a suitable weaving motion when required

A stick Welding arc is struck by hitting or scratching the striking end of the welding rod against the joint surface.

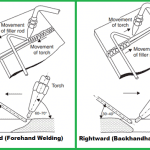

The stick welding rod is held at a suitable angle with respect to the work and the line of the joint, depending on the type of joint and position of welding.

At the end of the weld Run, the welding arc is made to linger momentarily to fill up the arc crater, and the electrode is withdrawn suddenly to extinguish the welding arc.

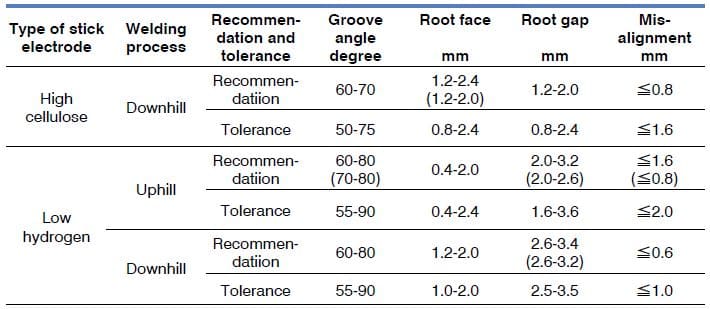

Stick Welding Chart showing recommended joint groove angle, root face, root gap and maximum high-low are given in the below table.

Stringer or Weaving beads in Stick Welding

The arc may traverse along a straight line without a weaving motion (called stringer weld beads), or it may be weaved sideways. A bead deposited without weaving is called a Stringer Bead and that deposited with weaving is termed a Weave Bead.

Stick Welding Polarity

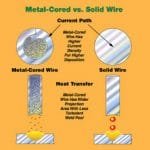

Both AC and DC (DCEP & DCEN) polarities are used in Stick Welding. DC is suitable for all types of stick welding electrodes and for welding all ferrous and non-ferrous metals. AC is not suitable for certain types of electrodes and for welding certain metals.

So before deciding to go in for an AC power source, one must make sure that the electrodes he is going to use and the metals he is going to weld are suitable for AC.

The electrode manufacturer indicates the suitability of each electrode type for AC or DC as well as also indicates the current range for each size of the electrode.

- In AC welding, because of the reversing nature of the current, flux coatings must contain enough arc stabilizers to re-ignite the arc immediately after the current comes to zero during each cycle.

- When using small-diameter electrodes at low amperages, DC has a definite advantage over AC, both for starting and maintaining the arc.

- For all electrode sizes, maintaining a short arc is easier with DC than with AC, except when iron-powder electrodes are used.

- Vertical and overhead welding on thick sections is easier with DC than with AC because a stable arc can be maintained at lower currents.

Effect of polarity in Stick Welding

DC polarity offers suitability to make welding electrodes positive or negative. For Stick welding, hence we can use DCEP or DCEN welding polarity based on the type of welding rod and weld requirements.

Straight polarity or also called DCEN (electrode negative) can be applied to Stick Welding of all steels (except when low-hydrogen electrodes are used), although will not suit for welding of nonferrous materials.

Using DCEN polarity, the electrode gets more heat thus resulting in more melting and weld deposition. Higher welding speed is possible. However, penetration is shallower and narrower.

DCEP or also called reverse polarity is used for low hydrogen type welding rods. It produces maximum penetration for a given set of conditions.

This characteristic makes reverse polarity the better choice for root passes in groove welds made with the use of backing bars, and for vertical and overhead welding.

In AC welding, a choice of polarity is non-existent because AC combines reverse and straight polarity in regular cycles. Hence AC gives penetration and electrode melting rate intermediate between those given by DCEP and DCEN polarity.

Can You Stick Weld Stainless Steel?

YES, you can stick weld stainless steel to stainless steel, stainless steel to carbon steel, or low alloy steel.

The stick welding rod selection for stainless steel welding depends on the grade of stainless steel material.

Click the below link to find the Welding rod Selection Chart for all types of materials.

For example, SS304 is welded with E308L-15 rod, SS310 is welded with E310 rod, SS316 is welded with E316L rod, SS321 is welded with E347 rod (E321 stick welding rod is not available in the market, as it is not possible to transfer titanium from rod to weld pool in a highly oxidizing stick welding arc, Titanium being a highly reactive element, will easily get oxidized in the welding arc zone during Stick Welding & it will not reach to the weld pool).

Can You Stick Weld Cast Iron?

Stick Welding can be used to weld Cast Iron and in fact, Stick Welding is the mostly used Welding process for the welding of Cast Iron for new construction as well as repairs.

ENiFe-CI (Also known as Nickel 55) and ENi-CI (Also known as Nickel 99) are the two most common stick welding rods used for Cast Iron Welding.

Click on the below link for detailed guidelines on the Cast Iron Welding using Stick Welding, soldering & Brazing.

Can You Get Electrocuted Stick Welding?

When Stick Welding, if there is no proper insulation available on the stick welder or welding on the wet areas without proper earthing, it is possible to get electrocuted.

It is very important not to temper the stick welder insulation or any supply cable and always work in safe conditions.

All Stick Welders are having restricted open-circuit voltage (OCV) to have a safe output voltage supply. A high OCV value poses the risk of electric shock to the welder and hence its value is restricted to maximum of 80 volts by the machine manufacturers.

Can You Use Tig Gloves For Stick Welding?

TIG Gloves are designed for welding processes that produce no to least welding spatters. While in Stick Welding (SMAW) there is a lot of welding spatters.

Stick welding requires leather hand gloves due to this reason and the Welder must not use TIG gloves for Stick Welding or MIG Welding.

Similarly, Stick Welding Gloves are less comfortable to allow good hand movement which is a must for TIG Welder.

They will provide a good protection against heat but being a manual operation, TIG requires more control on hand movement. So Stick Welding gloves will not suit for TIG Welding.

Does Stick Welding Require Gas?

Stick Welding does not require a Welding Gas supply for shielding the weld pool. In Stick Welding (SMAW) which is a Self-Shielded arc Welding Process, shielding gas is produced by burning of rod coating.

The burning of Stick Welding rod coating produces Carbon dioxide (CO2), Carbon mono dioxide (CO), oxygen (O), and Hydrogen that protects the weld pool from contamination.

Material Welding is run by highly experienced welding engineers, welding trainers & ASNT NDT Level III bloggers.

We strive to provide most accurate and practical knowledge in welding, metallurgy, NDT and Engineering domains.