Design of Fillet Welded Connections

The calculation of a fillet weld size or let us say dimensions for throat size (a) or leg length (z) is the task of the design engineer for the welded part. This calculation is based on the type & amount of loading, material thickness and other operational factors.

The design strength of a fillet weld depends on the (as highlighted in the below sketch):

Design strength = Theoretical throat (a) X Effective weld length (L)

Concave or Convex or flat fillet weld

Concave fillet weld is better for stress flow compare to convex fillet weld conditions that which the size of the fillet welds meets the minimum throat size.

Although due to less weld volume in the weld throat zone, during weld solidification & shrinkage stresses, concave fillet welds are prone to have cracking issues if sufficient weld volume is not present to withstand those stresses.

On the other hand, For Convex type fillet weld, welding shrinkage shall cause compression. Concave fillet welds are better for alternating stresses in welded components.

Fillet Size Formula

Fillet weld size formula (S) = (0.707 * T) / sin(A/2)

Where:

- S refers to weld throat thickness

- T refers to material thickness

- A refers to included angle of the fillet joint. (usually, 90 degrees)

To convert, Throat size (S) to Leg length (Z), you can use the formula Z ≈ 1.4 S.

Minimum size of fillet weld

Often, in fabrication, it happens many instances where a fillet weld size is not clear on the given in the drawings. , Sometimes, the weld size details are missing.

Under such conditions, we should consult the designer for the required fillet weld size. Otherwise, as a thumb rule, weld a minimum of 2 weld passes with a leg size of 0.25 inches (6 millimeters).

Minimum fillet size required according to AWS D1.1: If fillet weld size is not specified in the drawing, the general guidelines of AWS D1.1, Table 7.7 shall be followed.

Fillet weld size for different thicknesses

The table below gives the minimum fillet size required for different base metal thicknesses.

American Institute of Steel Construction (AISC) 360-16 Specification for Structural Steel Buildings you’ll find this in Table J2.4 as given below:

Maximum size of fillet weld

The maximum size of the fillet weld will be= 0.7 x T, where ‘T’ is the base metal thickness. In the case of dissimilar thicknesses, we should consider the thinner base metal thickness. Click here for Weld Size calculation.

Types of loading in fillet welds

Fillet welds joints are most commonly used in fabrication and structures. A fillet weld joint can be loaded in any direction in shear, compression, or tension loading. However, fillet weld always fails in shear loading.

The shear failure of the fillet weld happens along a plane through the throat of the weld, as shown in the Figure below.

If you know the value of Load (P), shear stress (fv), and length of weld, you can calculate the weld throat size using the above equation.

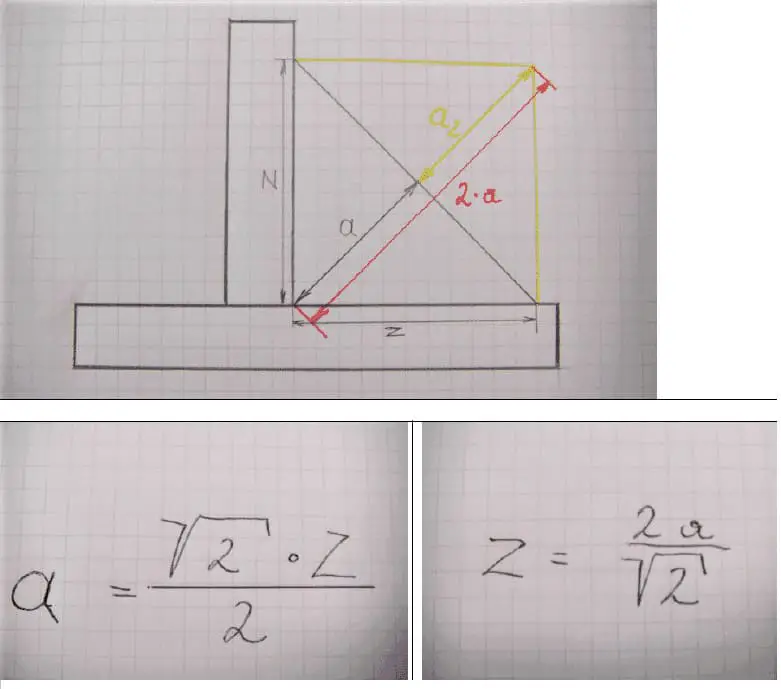

Throat size (a) to Leg length (Z) conversion formula

The throat size ‘a’ size is calculated from the previous corner of the workpiece before welding until the 45° created middle of the welding seam.

The sidewall – connection between the welding seam and the base material is called – ‘z’. The ‘a’ size is nothing more than the Hypotenuse of an isosceles triangle.

For a fillet weld with equal leg lengths, the cross-section triangle is a right-angle triangle with angles of 45 degrees in each corner. The relationship between weld throat ‘a’, and leg length z is given by:

a ≈ 0.7z and z ≈ 1.4 a

(For the maths-minded, 0.7 is 1/√2 and 1.4 is √2).

So, if we know the value of shear strength required as per design, we can calculate the throat size required for a fillet weld joint.

Material Welding is run by highly experienced welding engineers, welding trainers & ASNT NDT Level III bloggers.

We strive to provide most accurate and practical knowledge in welding, metallurgy, NDT and Engineering domains.