Oxy-Fuel Torch Cutting Tip Selection

There is a vast selection of cutting tips with varying shapes, lengths, and designs available for different purposes. These variations are a result of designing the cutting tip to meet the specific needs of a particular job.

For instance, cutting tips meant for thin-gauge metals will differ in design from those for thicker gauges, and special tips for gouging, scarfing, and rivet-washing will have different designs from standard cutting tips.

Generally, cutting tips are of the straight-bore type, with a slight taper towards the cutting orifice. However, there are also curved-bore designs available for special cutting jobs. To help select the appropriate cutting tip for a particular job, welding equipment manufacturers provide charts that list cutting tip specifications and recommendations for their selection.

How To Choose an Oxy-Fuel Torch Cutting Tip?

When choosing an oxy-fuel torch-cutting tip, task yourself below questions to help you to make the right cutting tip selection:

- The thickness of material to be cut.

- Type of Gas available.

- Type of Cutting to be carried out.

- Gas cutting speed requirements.

- Type of cutting torch.

Here, I have explained these points in depth.

- Material Thickness: The thickness of the material being cut is an essential factor to consider when selecting a cutting tip. Thicker materials require a larger cutting tip, while thinner materials need a smaller one. The higher the material thickness, the lower the tip size number.

- Gas Type: The type of gas being used for the cutting process also affects the selection of the cutting tip. Different gases have varying burning temperatures, and selecting the right tip can ensure that the gas burns efficiently. Acetylene gives the highest heat compared to LPG and propane.

- Type of Cut: The type of cut required, such as straight cuts, bevel cuts, or irregular shapes, also influences the choice of cutting tip. Some tips are specifically designed for gouging, scarfing, or rivet-washing, while others are suitable for general cutting purposes.

- Cutting Speed: The cutting speed required for the job also plays a role in selecting the appropriate cutting tip. A larger tip can cut through thicker material more quickly but may not provide the desired precision for thinner materials.

- Torch Type: The type of oxy-fuel torch being used can also impact the choice of cutting tip. Some torches may require specific tips for optimal performance.

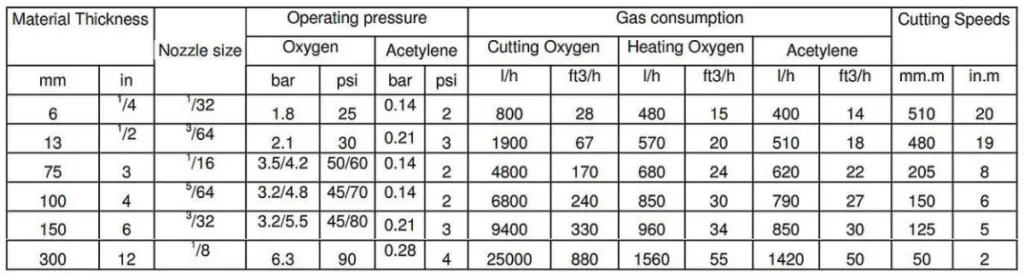

Gas Cutting Tip Selection Chart

Below, I want to show you a helpful chart that displays the best cutting tip selection based on the material thickness, the diameter of the cutting tip orifice in inches and the estimated cutting speed in inches per minute.

This chart is a reliable tool that I use to determine the appropriate cutting tip to achieve optimal results. With this chart, I can quickly select the right cutting tip for a specific job and ensure the cutting process is efficient and precise.

Another chart below also covers operating pressure for cutting as well as gas consumption (oxygen and acetylene) for cutting & heating.