Learning How to Weld aluminum is not as difficult as it may seem. In fact, with the right welding filler wire rod, technique and a little practice, anyone can learn to weld aluminum.

It is very important to have pre-hand information for which Aluminum material grade you are going to weld. With this info, you can use the right aluminum rod required for the task with the information provided in this post.

What are the Challenges in Aluminum Welding?

The main issue affecting the welding of aluminum alloys are the:

- High affinity to oxygen leading to a persistent very thin oxide layer (AL2O3) on the surface which melts at 1926°C, whereas pure aluminum melts at 660°C. So, if the oxide layer not removed, the plate material will melt and the oxide remains un-melted, hence will not form a weld joint.

- Solidification cracking in some grades with low manganese.

- Loss of weld joint strength in the HAZ.

- High risk of invisible porosity (Mostly internal porosity, the weld will look excellent from outside but will be full of porosity inside the weld, which gets visible in radiography or fracture or macro test).

So, aluminum must be taken care of, especially when compared to steel. It has high thermal conductivity so the heat from the welding zone dissipates very fast.

Its high thermal expansion can result in distortion. As aluminum doesn’t change color when melted or heated, it is not possible to assess temperature during welding.

Comparison of physical properties of Aluminum and carbon steel affecting weldability

Aluminum Material Specifications & Grades

The most commonly used material specifications for Aluminum are: ASTM B209, ASTM B210, ASTM B211, ASTM B221, ASTM B234, ASTM B241, ASTM B247 and ASTM B928.

The material designation follows the Aluminum Association 4-digit classification. The first digit here specifies the major alloying elements as shown in above table 1.

For temper designation, a specific letter indicates the condition of the alloy. Various letters used are as follows:

- F – As fabricated – no control on mechanical properties.

- O – Annealed, soft.

- H – Strain hardened.

- T – Heat treated to produce stable tempers.

Some examples:

- 1100-O 99%min Al+0.12% Cu, annealed.

- 2024-T3 Al-4.4Cu-1.5Mg-0.6Mn, solution heat-treated, cold worked, and naturally aged.

- 5052-H34 Al-2.5Mg-0.25Cr, half hard.

- 3003-H14 Al-1.2Mn, half hard.

- Half hard means partially cold worked

Selection of Welding Consumables

Hot cracking can be prevented by using 4043 type filler wire, but it will give lower ductility and toughness compared to 5356 type wire. 4043 types due to high silicon content give the poor color match to 5XXX and 6XXX aluminum base metals after anodic oxidation treatment.

When welding 5XXX (high Mg, more than 3% usually), 4043 is a poor choice as it will make an intermetallic compound of mg2Si in the weld metal. This will lower the weld metal ductility and increase its crack sensitivity.

Which Welding Process is best for Aluminum Welding?

Aluminum can be welded with TIG and MIG welding easily. TIG welding with AC current is used for thinner section welding. Using AC current gives half a cycle of cathodic cleaning in both manual and automatic processes. MIG is used for heavier sections.

Advance welding processes such as laser welding & Friction stir welding are nowadays used heavily in Aluminum fabrication.

Aluminum Stick Welding

Aluminum can be welded using Stick Welding or also SMAW. Aluminum stick welding rods are available in market. C

TIG Aluminum Welding Parameters

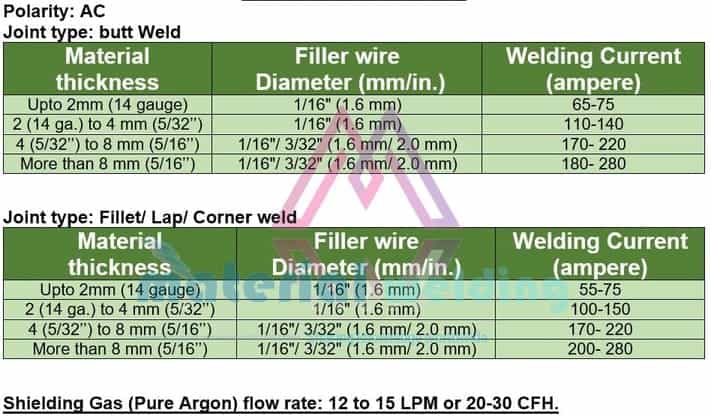

MIG Aluminum Welding Parameters

Which Shielding gas to be used for Aluminum Welding?

Pure Argon is widely used. Argon-Helium mixture in MIG welding. Helium addition helps for a better weld formation and increases the welding speed.

Helium also minimizes the risk of pores and lack of fusion. Pure helium is not used due to the high Ionisation potential of the gas as well as the high cost of the gas.

What is Preheating temperature for Aluminum Welding?

Preheat is recommended for thicker sections or whenever sufficient penetration can not be achieved due to the high thermal conductivity of the aluminum.

So, if any of the above issues are being faced, a preheat temperature of 150 to 200°C can be applied. Also, when repairing 5XXX (Al-Mg) grades, it can crack in the weld or HAZ area. Following a preheat in these conditions is very beneficial to mitigate the cracking inter-alia to using the right filler wire.

For welding of Aluminum 5000 grade having Mg content more than 3%, make sure not to preheat more than 250°F or 125°C.

What is Interpass temperature for Aluminum Welding?

Usually, the interpass temperature is kept above the minimum preheat temperature when welding aluminum.

Aluminum Welding troubleshooting

HAZ softening & decrease in welding tensile strength

HAZ of aluminum is prone to heat-affected zone softening unless it is annealed. Figure 1 shows how the HAZ softening occurs in non-heat-treatable aluminum alloys such as 3003 type welded with ER1100 filler wire.

In the heat, treatable alloy, e.g. 6061-T4, commonly used aluminum grade, exhibits a decrease in HAZ hardness resulting in HAZ softening.

Due to these softening issues, the welding joint T.S. falls for aluminum and its alloys in the as-welded condition. Al-Zn-Mg grades gain their strength after time being due to natural aging hardening characteristics.

Hot cracking in Aluminum Welding?

Hot cracking is faced during aluminum welds at a temperature near to the base metal & filler metal solidus temperature when the weld cools.

Hot cracking is mostly faced due to the segregation of alloying elements along with the low melting phases at the grain boundaries.

How to avoid porosity in Aluminum welding?

Aluminum and its alloys are highly susceptible to weld metal porosity (bubbles of hydrogen) due to the high solubility of hydrogen in it.

Shielding gases having a minimum dew point of -60°C shall be used. To avoid porosity issues, especially when using MIG following shall be taken care of:

- Shielding gases shall be free from contamination. Gas fitting, hoses & connections shall be free from dust, moisture, oil, etc. Use plastic (such as Teflon) hoses instead of rubber & vinyl chloride hoses, which can absorb moisture. Let shielding gas (a flow to up to 5 LPM) to flow for 10-15 minutes before welding through the welding gun.

- Base metal, filler wire shall be free from any moisture.

- Humidity shall be controlled since atmospheric moisture can reach the weld pool & result in porosity.

- It’s recommended to use forehand welding techniques that offer good oxide cleaning action.

- Improper/ insufficient/ contaminated gas shielding can cause smut (oxides of aluminum & magnesium), visible as black color as shown in the below figure. It can be avoided using 4000 series welding wire which contains no mg. while 5000 series contain high Mg.

Which are the Shielding gases for TIG & MIG welding of Aluminum?

Pure Argon is used mainly as shielding gas for welding of aluminum by TIG & MIG welding.

A gas or gas mixture used for shielding shall be of a welding grade and have a minimum purity of 99.997% and a dew point of –76°F [–60°C] or lower for argon and a minimum purity of 99.995% and a dew point of –71°F [–57°C] or lower for helium (see A5.32, Specification for Welding Shielding Gases).

Material Welding is run by highly experienced welding engineers, welding trainers & ASNT NDT Level III bloggers.

We strive to provide most accurate and practical knowledge in welding, metallurgy, NDT and Engineering domains.