Painting is a critical step in the construction process as it not only enhances the aesthetic appeal of a structure, but also serves as a protective barrier against the corrosion and adverse weather conditions.

However, even with proper planning and execution, painting defects can still occur.

Painting defects list

Here is a list of common painting defects, their causes, and ways to prevent them:

- Alligatoring

- Blistering

- Chalking

- Cracking

- Fading

- Peeling

- Sagging

- Wrinkling

- Chipping

- Dripping

- Erosion

- Staining

- Flashing

- Lap marks

- Sagging

- Yellowing

- Flaking

- Bubbling

- Efflorescence

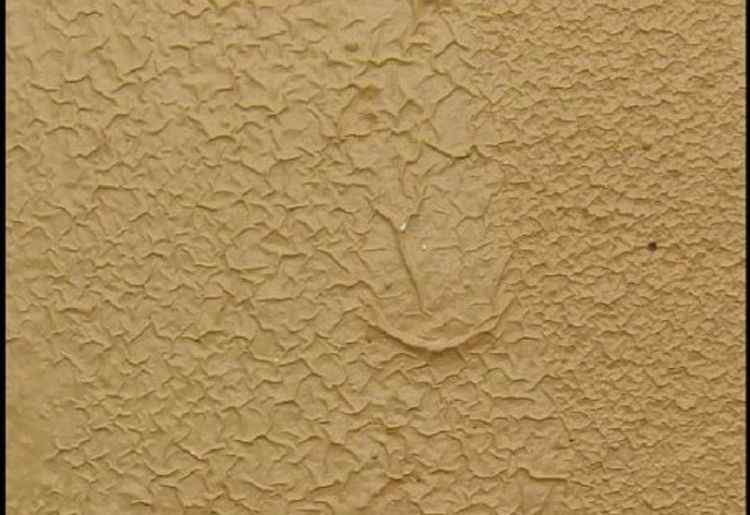

Alligatoring

Alligatoring defect is characterized by a pattern of cracks that resemble the skin of an alligator.

It is caused by the failure of the topcoat to adhere properly to the underlying coat.

To prevent alligatoring, ensure that the surface to be painted is clean, dry, and free of any contaminants, and that the paint used is appropriate for the surface and weather conditions.

Blistering

Blistering defect occurs when bubbles or blisters form on the surface of the paint, often due to moisture or heat buildup.

Blistering can be caused by poor surface preparation, insufficient curing time, or the use of incompatible paint products.

To prevent blistering, ensure that the surface is clean and dry, and that the paint used is appropriate for the surface and weather conditions.

Chalking

Chalking is the formation of a powdery residue on the surface of the paint, caused by the breakdown of the binder in the paint.

It can be caused by exposure to UV rays, high temperatures, and humidity.

To prevent chalking, use paint formulated with UV inhibitors, and ensure that the surface is clean and dry before painting.

Cracking

Cracking defect is characterized by the formation of fine, hairline cracks in the paint.

It can be caused by poor surface preparation, improper paint application, or the use of low-quality paint.

To prevent cracking, ensure that the surface is clean, dry, and free of any contaminants, and that the paint used is appropriate for the surface and weather conditions.

Fading

Fading refers to a loss of color and gloss in the paint, caused by exposure to UV rays, heat, and moisture.

To prevent fading, use paint formulated with UV inhibitors and ensure that the surface is clean and dry before painting.

Peeling

Peeling defect occurs when the paint loses adhesion and starts to separate from the surface.

It can be caused by poor surface preparation, insufficient curing time, or the use of incompatible paint products.

To prevent peeling, ensure that the surface is clean, dry, and free of any contaminants, and that the paint used is appropriate for the surface and weather conditions.

Sagging

Sagging defect occurs when the paint droops or sags, often due to improper application or the use of paint that is too thick.

To prevent sagging, use paint of the appropriate consistency and ensure that it is applied in thin, even coats.

Wrinkling

Wrinkling defect is characterized by the formation of wrinkles or creases in the paint.

It can be caused by poor surface preparation, improper paint application, or the use of paint that is too thick.

To prevent wrinkling, ensure that the surface is clean, dry, and free of any contaminants, and that the paint used is appropriate for the surface and weather conditions.

Chipping

Chipping defect is characterized by small flakes or chips in the paint, often caused by impact or abrasions.

Chipping can also be caused by poor surface preparation, inadequate priming, or the use of paint that is not suitable for the surface.

To prevent chipping, ensure that the surface is clean, dry, and free of any contaminants, and that the paint used is appropriate for the surface and weather conditions.

Also make sure to use a primer that is suitable for the surface and the paint that will be applied over it.

Watch this video on YouTube for Painting & Coating Defects.

Dripping

Dripping defect, also called sagging occurs when the paint drips or runs, often caused by improper paint application or the use of paint that is too thick.

To prevent dripping, use paint of the appropriate consistency and ensure that it is applied in thin, even coats, and adjust the nozzle of the paint sprayer or roller to the correct setting.

Erosion

Erosion defect is characterized by the gradual loss of paint due to exposure to the elements, often caused by poor surface preparation or the use of paint that is not suitable for the surface.

To prevent erosion, ensure that the surface is clean, dry, and free of any contaminants, and that the paint used is appropriate for the surface and weather conditions.

Flashing

Flashing defect is characterized by glossy or shiny areas in the paint, often caused by improper paint application or the use of paint that is too thick.

To prevent flashing, use paint of the appropriate consistency and ensure that it is applied in thin, even coats. Also, use a paint that is formulated to produce a uniform finish.

Lap marks

Lap marks defect is characterized by visible marks or bands in the paint, often caused by paint application over an area that has already begun to dry.

To prevent lap marks, ensure that paint is applied in thin, even coats and work on small sections at a time to avoid the paint from drying too quickly.

Additionally, use paint brushes or rollers of the appropriate size and nap to help achieve a consistent and uniform application.

Bubbling

Bubbling is a common defect in painting that occurs when air or moisture is trapped under the paint film, causing it to lift and form bubbles. This can happen for a number of reasons, including:

- Improper surface preparation: If the surface is not properly cleaned and primed, the paint may not adhere properly, allowing air and moisture to get trapped.

- Using paint that is too thick: Applying paint that is too thick can cause it to take too long to dry, allowing air and moisture to become trapped underneath.

- Applying paint in humid conditions: High humidity can cause paint to dry too slowly, allowing air and moisture to become trapped.

- Exposure to moisture: Exposure to moisture, either from rain or from high humidity, can cause bubbling in paint.

To prevent bubbling, it’s important to properly prepare the surface before painting, use paint that is the appropriate consistency, and avoid applying paint in humid conditions. If bubbling does occur, the affected area will need to be sanded down, cleaned, and repainted.

Flaking

Flaking is a defect in painting that occurs when paint chips or peels away from the surface due to poor adhesion, exposure to moisture, or frequent temperature changes. This can happen for several reasons, including:

- Poor surface preparation: If the surface is not cleaned, sanded, and primed properly, the paint may not adhere properly and may start to flake.

- Use of incorrect paint type: Using a paint that is not suitable for the surface or environment can cause it to flake over time.

- Exposure to moisture: Exposure to moisture, either from rain or high humidity, can cause paint to flake due to the paint film becoming swollen and then contracting as it dries.

- Extreme temperature changes: Rapid temperature changes can cause paint to expand and contract, causing it to flake.

Efflorescence

Efflorescence is a type of painting defect that is characterized by the appearance of white streaks or discoloration on the painted surface. This occurs when salts and minerals are deposited on the surface of the paint film.

But why does this happen, you may ask? Well, it can be due to several factors, such as the presence of moisture in the underlying masonry or the use of low-quality paint that is not resistant to efflorescence.

It’s important to note that efflorescence is not just an aesthetic issue – it can also indicate that there may be underlying problems with the masonry, such as excessive moisture or poor ventilation.

To prevent efflorescence, it’s recommended to use high-quality paint that is formulated to resist efflorescence, and to properly ventilate the area to prevent excessive moisture buildup.

Staining

Staining in painting is a frustrating issue that can be caused by a variety of substances, such as dirt, grease, or other substances that penetrate the paint film and discolor it. This can be a real bummer, as it detracts from the overall look of the painted surface.

One common cause of staining is poor surface preparation before painting. If the surface is not properly cleaned and primed, it can be more susceptible to staining. Additionally, using low-quality paint that is not resistant to staining can also contribute to the problem.

But don’t despair! There are steps you can take to prevent staining. Firstly, make sure to properly clean and prime the surface before painting. Additionally, choose a high-quality paint that is formulated to resist staining and has good adhesion properties.