What is Socket Weld

A socket weld is a type of pipe fitting weld joint type where the pipe is inserted into the fitting recess and then a sealing weld is made by a all around fillet weld deposit.

This creates a strong, sealed connection that is ideal for high-pressure applications. The main advantage of socket weld fittings is that they do not require any threading on the outside of the pipe, which makes them easier to install & help to make a permanent weld joint.

Socket welds are used in a variety of applications, including plumbing, oil & gas, automotive and aerospace. They are also used in many industrial applications.

Socket welds are commonly used in the construction of pipelines and other types of piping systems.

How to make a Socket weld: Step by Step

Socket weld is a type of welding in which a pipe is inserted into a recessed area of another pipe fitting, valve or flange. This allows for a strong, permanent joint to be formed between the two pieces of pipe & pipe fitting.

To install a socket weld fitting, the first step is to clean the inside of the recessed area and the end of the pipe that will be inserted into it.

This ensures that there is no debris or dirt that could prevent a good seal. Next, the pipe is inserted into the fitting until it reaches the bottom of the recessed area (You will notice it a machined step on fitting internal).

Once in place, a fillet weld is used to create a strong seal between the two pieces.

Socket Weld vs. Butt weld

Socket weld is a method where the pipe is inserted into a recessed area on the other piece of pipe. Socket welds are typically used for smaller diameter pipes and tubing while butt welds are used for higher diameter and thicknesses.

| Socket Weld | Butt Weld |

|---|---|

| Low strength weld | High Strength Weld |

| Fillet weld configuration | Groove Weld configuration |

| Socket weld fitting details given in ASME B16.11. | Butt weld fitting details given in ASME B16.9. |

| Suitable for small diameter piping | Used for higher diameter piping |

| Not used for high temperature | Suitable for high temperature |

| Low joint efficiency | High joint efficiency |

| No Weld-Bevel preparation required | Weld-Bevel preparation is required |

The main advantage of a socket weld is that it is much easier to make than a butt weld. The disadvantage is that it is not as strong as a butt weld and is more likely to leak.

Butt weld joints requires weld bevel preparation before welding and possible for similar material thickness only. While a Socket weld does not requires special weld preparation & much faster in fitment compared to butt weld joints.

In terms of strength, butt weld are much stronger than the socket weld joints.

Socket Weld vs. Fillet weld

Socket weld is a type of welding joint fitment for piping connections. On the other hand, fillet weld is a type of weld deposit made on a welding joint.

So- a Socket Weld is a type of weld joint & Fillet weld is a type of weld made on a these joints.

Sockets welds due to their configuration requires to be welded as a Fillet Weld. So, all socket weld joints are Fillet weld type.

Types of Socket Weld Fittings

Socket weld fitting are supplied & manufactured as per ASME B16.11 standard. There are three types of socket weld fittings:

- Straight Socket Weld Fittings: Boss, Coupling (Reducing, Half & Full), Couplet, Union

- Distribution Socket Weld Fittings: Cross, Tee

- Elbow Socket Weld Fittings: 45° or 90°

- Socket Weld Flange

Socket Weld Fittings

A socket weld fitting is the type of connection having a recessed area made by machining so the pipe or tube can rest in the slot and then welded from outside using a fillet weld. This type of connection is typically used for small diameter pipes and tubing. It is also commonly used in high pressure applications.

The main types of Socket Weld Fittings are:

- Coupling (Full, Half & reducing type)

- Union

- Elbow: 45° or 90° (short & long radius)

- Tee

- Cross

- Cap

Socket Weld Flange

A socket weld flange is a type of pipe flange that is welded to a pipe by inserting the pipe into a recessed area of the flange. This allows for a stronger connection as the two pieces are welded together. Socket weld flanges are typically used in smaller size & high-pressure applications.

Socket Weld Elbow

A socket weld elbow is similar to normal fitting elbow except that it has a recess or step made on internal id on both sides for pipe fitting.

Socket Weld Union

A socket weld union is a type of mechanical pipe fitting that is used to join two pipes or tubes together. This union is made by welding a small socket onto the end of one pipe, which is then fitted over the other pipe and welded in place.

Socket weld unions are strong and leak-resistant, making them ideal for use in high-pressure applications but need to be tightened for seal proof joint.

A socket weld union is a three-part fitting that consists of a body, a nut, and a sleeve. The nut is then threaded onto the body and tightened to create a seal. The sleeve is placed over the welding area to protect it from corrosion.

Socket Weld Inspection Procedure

In order to ensure the strength and reliability of a socket weld, it is important to follow a strict inspection procedure.

The inspection shall be carried out at:

- Before welding

- After Welding

At before welding step, the inspection process is to check the fit-up of the socket fitting, pipe or tubing being joined. This includes checking for gaps, misalignment, and irregularities. If any problems are found, they should be corrected before welding begins.

After welding socket weld inspection shall be:

- Visual Inspection (VT)

- NDT Testing: PT, MT for surface defects & Radiographic Testing (RT) for internal defects.

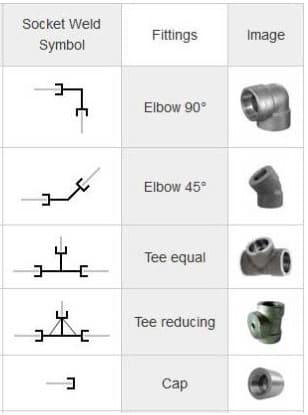

Socket Weld Symbol

Symbol of socket weld represented by type of socket weld fitting. A 90° socket weld elbow has a weld symbol in L-shape. Equal T socket weld symbol resembles to the T-Shape of equal T.

Different types of Socket Weld symbols are shown in the below picture.

Material Welding is run by highly experienced welding engineers, welding trainers & ASNT NDT Level III bloggers.

We strive to provide most accurate and practical knowledge in welding, metallurgy, NDT and Engineering domains.