What is Weld Purging?

Weld purging is a technique used to make high quality welds with minimal oxidation and discoloration. It involves the use of inert gases such as argon, helium or nitrogen to protect the weld area from oxygen while it is being heated or in oxidation prone temperature range.

The weld purging process helps to eliminate oxygen that can cause defects in the welded joint and also reduce discoloration caused by oxidation of the metal.

The most common method of welding purging is called “back-purging”. In this technique, an inert gas is applied on the backside of the joint before welding begins.

This prevents oxygen from entering into the weld zone and keeps it free from contamination. Additionally, back-purging can help reduce distortion in weld metal due to excessive heat input during welding.

Why purging of welds is required?

Metals such as chromium (main alloying elements for stainless steel), aluminum, magnesium, etc. are highly reactive with oxygen when heated. Heating mainly occurs during welding and hence it is must to prevent the hot metal to come in contact with oxygen.

When welding to stainless steel, titanium and other corrosion-resistant metals (Magnesium, tantalum), purging is required to preserve the metal’s original purpose of corrosion resistance properties in order to create a complete welding environment, which is the most important thing.

The only option to overcome this is to use weld back-purging to eliminate the oxidation. Note– If purging is not done properly, the weld seam will be exposed to oxygen and oxides due to the heat of the weld during welding.

Oxidation must be prevented in advance or treated later by pickling & passivation or grinding. Although these later methods are costly and may not work well if oxidation level is very high. Successful welding requires proper purging equipment and technique.

Preventing Oxidation during Welding

Weld seam oxidation during metal welding occurs if oxygen is not prevented where this welding takes place. This situation makes titanium, zirconium, magnesium and other reactive metals and alloys more sensitive. The resulting oxidized surface is no longer continuously corrosion resistant and requires further treatment.

Removing oxidized parts by grinding also removes the metal’s own passive protection against corrosion. Other mechanical procedures, such as brushing, blasting and pickling, eliminate oxidation and this process can increase corrosion resistance but increase the cost.

However, in the case of pipe welding, it may be difficult or impossible to remove the oxidation after welding. Oxides generated during welding are usually located in places that are almost inaccessible.

For example, access to the internal welds of a 3-meter pipe spool with a 4-inch diameter pipe would not be possible. Pickling increases corrosion resistance, but it takes time and will not be possible, especially in remote workshops on site.

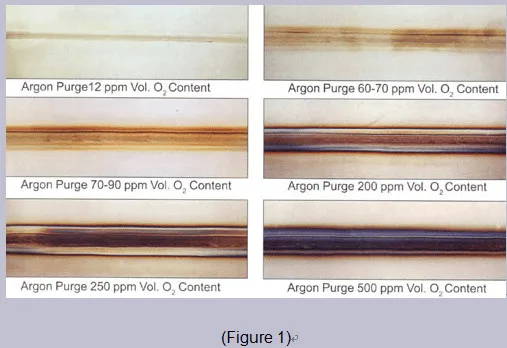

Instead of removing the oxidation later, another way is to prevent oxidation in the first place using inert gas back purging during welding. Inert Purging gas is used to protect weld seams by cooling them until oxidation no longer occurs. It uses argon gas (Ar), an inert gas that is heavier than normal air. (See Figure 1 below for effect of purging gas purity on oxidation level.)

Nitrogen, another purge gas, and nitrogen/hydrogen mixtures can also be used. For small piping, mainly argon is used for weld purging applications.

Weld Purging Equipment

A common approach is to tape the ends and purge the entire pipe length with purging gas before start of welding. However, these methods can be time-consuming and uneconomical methods can result in wasting purging gas, unproductive labor hours and less desirable results.

Appropriate weld purging equipment and accessories shall include:

1. A purging unit. (purging equipment)

2. Aluminum tape. (For blocking weld GAP)

3. An oxygen indicator. (Oximeter)

The purging unit should reduce the amount of internal oxygen, provide a well-sealed space, and not produce contaminants. The purging gas must be injected slowly at an appropriate rate in the purging chamber to reduce argon and oxygen mixing and reduce escaping convection, which is a major factor in the quality of the purging operation.

At the same time, the place being purged must be sealed to prevent further ingress of oxygen. In order to increase the speed of the purge time, the loss of argon gas must be reduced as much as possible and new oxygen entering the welding site must be prevented.

The outside of the joint of the pipe must be sealed using aluminum tape that can withstand welding temperatures and is halogen-free. Conventional tapes should not be used because they contain halogens, especially chlorine. Like hydrogen and oxygen, chlorine is absorbed by reactive metals at high temperatures, causing embrittlement on the surface of welds.

Therefore, all components used in the manufacture of this purging mechanism must be halogen-free, resistant to heat and must not contain dissimilar metals. The oxygen discharge hole must be included for oxygen to be discharged from the purging environment and for the purging gas to enter.

When welding and purging corrosion-resistant materials, the following should be configured:

1. Purging gas content during welding.

2. Oxygen penetration and diffusion through internal gas supply lines, connecting mechanisms, regulators, purging mechanisms, welding gaps including gas hoses, sealing mechanisms, connections to welding machines

Residual oxygen is measured at the joint where the final measurement is welded, and may contain trace oxygen content due to trace leakage in the hose/regulator connection or incorporation through the welding gap.

For this reason, it is important to establish procedures for oxygen indicators. The sensor of this oxygen indicator must be accurate enough to measure oxygen in PPM. If the oxygen indicator is measurable at 0.1 percent (1,000 PPM) or 0.01 percent (100 PPM), it may not be accurate enough because most weld levels can perform well below 70 PPM. High accuracy allows each additional oxygen content to be identified and prevents welding failures or rework.

To ensure optimum weld quality, TIG welding or also called gas tungsten arc welding (GTAW) electrodes must be long-ground into the front with a circumference. The geometry of the grinded tip must be finished at a high level to help ensure proper arc stability.

Electrodes ground with tungsten electrode grinders with Diamond wheels provide better arc penetration for longer lasting and optimum weld quality.

Weld Purging Techniques

A common problem with purging concerns the flow rate at which the welder purges. This flow rate is highly dependent on the amount actually purged.

In fact, the welder must strive for a sufficient flow to maintain the flow in which oxygen is discharged obediently, and where it is purged, to keep the pressure inside stronger than the outside. This action prevents new oxygen from entering the weld seam and at the same time minimizes the excess convection that destabilizes the weld arc.

Another common issue concerns the length of the purge time. In addition to using hands-on experience to determine the purge time, welders can use many calculated formulas to find the exact moment of welding. However, weld quality actually depends on many factors such as moisture, quantity, and materials, not just a few considerations.

THE CORRECT LENGTH OF A TYPICAL PURGE TIME IS BELOW 70 PPM WITH AN OXIMETER FOR STAINLESS STEEL AND 50 PPM FOR TITANIUM. In this case, it may take 2~4 extra hours when using purging unit. (Although it depends on Size). Other industries, such as semi-conductor, require levels below 10 PPM. It will take longer to reach these ranges.

Welding parameters must be determined by a welding engineer and monitored by a quality inspector. In addition, purging requires that the weld seam be sufficiently cooled to prevent further oxidation. For joints composed of multiple welding layers, according to the special welding procedure and elasticity of the material, the weld seam must maintain a purge gas flow of 3/8 ~ 1/2 inch thick.

Pipes preheated at high temperatures are sometimes recommended to have a residual oxygen content below 100 PPM to create the formation of chrome oxides.

Leaks in oxygen gas hoses and supply lines should be closely monitored. The moisture present by oxygen can permeate gas supply lines and prevent compliance with clean processes required by codes and specifications.

This can occur especially when purge gas lines have not been used for a significant period of time or when they are used in humid environments. In this case, the residual gas must be drained before welding before use for a suitable gas flow.

Weld Quality

Stainless steel, titanium, nickel, zirconium, molybdenum, tantalum and the nuclear, refining, pharmaceutical, semiconductor, aerospace, and food and beverage industries require the appropriate tools to create a complete welding environment for effective welding of these alloys.

Purging equipment and their proper use can be a major factor in improving final weld quality and preventing oxidation.

Reference for the purging method in Welding code

1. API RP582, para. 7.3: Required for more than 2-1/4% Cr contained steels unless the joint is ground or back gouged to sound metal.

2. AWS D10.8-1996, para. 4.2: Not required for under 4% Cr contained steels.