Electron Beam Welding

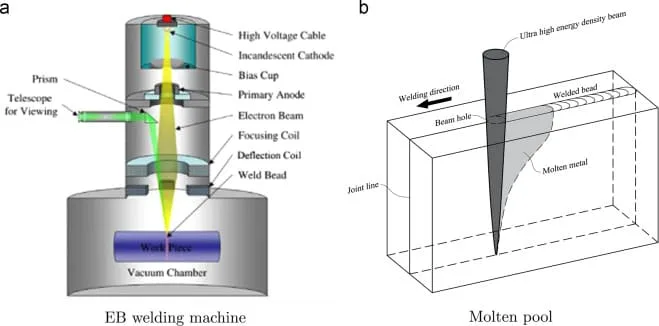

In this process, fusion is achieved by focusing a high-power density beam (red color beam in below diagram) of electrons on the area to be joined.

The energy required for welding is transmitted to the workpiece by an electron beam, released from an electron gun, concentrated, accelerated to about half the speed of light (150,000 km/s) and directed at the workpiece to be welded. In case of sufficient power, the part will melt locally and will partially evaporate.

Upon striking the metal, the kinetic energy of the high velocity electrons changes to thermal energy, causing the metal to melt and fuse.

The electrons are emitted from a tungsten filament (Cathode) heated to approximately 2,000° C.

Since the filament would quickly oxidize at this temperature if exposed to normal atmosphere, the unit as well as the focusing devices and workpiece are placed in a vacuum.

Also, because an electron beam is rapidly dispersed in the gas, this process almost always takes place in a vacuum.

The main advantage of vacuum welding is that no oxidation or interaction with oxygen or hydrogen occurs.

This function is ideal for welding materials that oxidize very quickly such as tungsten, molybdenum, titanium, zircon, which for example are used in the aerospace industry.

Applications range from welding thin sheets, to assembling parts with a thickness of more than 100 mm in a single cycle. Thus, it is possible to weld almost the entire spectrum of metals and various combinations of materials.

Principle of the Electron Beam Welding Process

| Type of operation | Automatic |

| Equipment | High voltage generator – gun electron – Vacuum chamber, vacuum pump, gasket or barrel positioning device |

| Cost of equipment | Very variable,150 000 € and more |

This process uses the energy of an accelerated electron beam. The fusion of the metal is achieved by the transfer of kinetic energy into heat when electrons impact the parts.

Generally, the parts to be welded and the electron gun are placed in the same enclosure where a vacuum of 10-6 Torr hold.

The process requires complete automation because everything is in a vacuum chamber, electron beam welding allows the assembly of steel sheets from about 1/10 to 300 millimeters thick, in a single pass. The power of the beam causes fusion almost instantly over the entire thickness.

This process is the most penetrating of the welding processes, with a fine geometry and almost parallel edges.

The penetration of the beam makes it possible to achieve narrow welds, the preparation of the edges must be carried out by precision machining.

The speed of execution and the low energy input considerably limit the thermally affected areas.

Electron Beam Welding Process Characteristics

| Beam Intensity range | 10 to 500 mA |

| Voltage | from 10 to 150 kV |

| Power | 3 to 500 kW |

| Thickness range | 0.2 to 200 mm (up to 8 inches) |

| Types of joint | butt welds |

| Welding positions | Limited by type of equipment (usually flat only) |

| Implementation | easy but the elements to be assembled must be introduced and evacuated into the vacuum chamber |

| Portability | No |

Electron Beam Welding Consumables

Filler wire can be added, if necessary, by using hybrid EBW.

Basic materials: Any material that accepts to be vacuum melted

What materials can be welded using EBW?

Electron beam welding can join materials ranging from thin foils to sheets of 50 mm thickness.

It is particularly suited for the welding of refractory metals such as tungsten, molybdenum, columbium, tantalum, and metals which oxidize readily, such as titanium, beryllium and zirconium.

It also has wide application in joining dissimilar metals, aluminum, standard steels and ceramics.

It can also be used for welding Alloy steels and stainless steels, Titanium, Copper, aluminum alloys, Inconel. Remarkable heterogeneous bonds such as copper + stainless steel alloys.

Application and uses for Electron Beam welding

An electron beam welder is very expensive, but its use is justified for critical applications. such as bimetallic blades for metal-cutting saws, aircraft engine components and supercharger impellers for diesel engines.

The automotive sector is also interested in this technique: a minimum of distortion is a big advantage when it comes to the mass production of gearbox gears.

Electronic components are also electron beam welded due to the high precision and low thermal energy input, which helps protect the electronics. On a few millimeters of the weld there is no thermal influence. Dissimilar materials can also be welded using this technique.

Advantages of Electron Beam welding

The main advantages of Electron Beam welding process are listed below:

- Low power consumption.

- High reproducibility due to high degree of automation.

- Excellent weld quality due to limited heat input and deformation.

- Thin welds with thermally narrow affected areas (less than 10:1).

- Deep welds, more than 100 mm.

- High welding speed up to 250 mm/s.

- Welding thick-walled parts at reduced costs.

- Its ability to produce deeper and narrower welds with total heat input which is much lower than in arc welding.

- Good control over weld penetration and other weld dimensions High-purity welds free from oxides and nitrides.

- An electron beam welder is very expensive, but its use is justified for critical applications.

- such as bimetallic blades for metal-cutting saws, aircraft engine components and supercharger impellers for diesel engines.

- Lately, non-vacuum electron beam welders have been developed, which give higher

Disadvantages of Electron Beam welding

Disadvantages of Electron Beam welding are listed below as:

- High cost of equipment.

- Vacuum device required.

- Extreme precision of the preparation of the edges to be assembled.

- production rates at lower costs, because no vacuum chamber is needed for the work and no time is lost in pumping down for each load. Also work size is not limited by chamber dimensions. The non-vacuum technique however gives reduced penetration, and the welds are not as narrow and non-tapering as those made with vacuum.

Health and safety

Electron Beam welding uses high intensity radiations to generate the heat. Hence, it possesses significant risks if not performed with safety. For example:

- X-ray emissions, but they are normally absorbed by the walls of the vacuum chamber.

- High voltage.

- Safety devices against operator confinement for large chambers.