Steel beam calculations form the backbone of any construction project, ensuring the integrity and durability of infrastructures wherever they stand. The calculations condense the cross-disciplinary knowledge of mathematics, physics, and civil engineering into actionable blueprints.

It may appear as a daunting topic for the general public, but in truth, when broken down, it can be quite fascinating. This article endeavors to demystify this subject, taking readers from the very basics of structural engineering and steel beam function, to the inner workings of beam calculation processes, and ultimately, the importance of accuracy in these calculations.

It will also shed light on the various types of steel beams in construction and the technological aids available for these calculations. Whether you’re an engineer looking for a refresher or a curious reader interested in construction, this article aims to provide a comprehensive understanding of steel beam calculations.

The Basics of Steel Beam Calculations

Basic Understanding of Structural Engineering and Steel Beam Calculification

Structural engineering is a field of civil engineering focused on the design, construction, and maintenance of load-bearing structures. Steel beam calculations are pivotal in this discipline, as steel beams are integral supports in most construction projects, spanning the distance between two points to provide load-bearing assistance.

Their capacity to resist loads and forces depends on various factors, including their size, length, shape, and the type of steel used. Critical factors include dimensions, load-bearing variances, and placement, as well as the specific weights they need to support, including live loads, dead loads, and environmental considerations like wind and seismic loads.

The Role of Steel Beams in Construction

Steel beams are fundamental to the stability and safety of a structure, taking on the role of primary load-bearing elements. This includes their ability to withstand static loads, such as the weight of the structure, and dynamic loads, which include external forces like wind or seismic activities.

In fact, the steel beam’s main function in modern infrastructure is to resist bending moments and shear forces. Their excellent strength-to-weight ratio, compared to other materials like concrete or timber, highlights their significance in high-rise buildings, bridges, and other large structures.

Decoding Key Terms: Shear Force, Bending Moment, and Load-Bearing Variances

To appreciate steel beam calculations, it is essential to understand a few key terms.

Shear force pertains to the internal forces experienced by a beam in response to loads that are applied perpendicular to its axis. In essence, it’s the force that may cause layers of the beam to slide against each other.

On the other hand, a bending moment is the reaction triggered by a force applied at a distance from the beam’s support, causing the beam to bend. The greater the distance from the support, the higher the bending moment.

Understanding load-bearing variances is another fundamental aspect of comprehending steel beam calculations. These variances, often determined by factors like geographical location and structure function, can substantially impact which type of beam is selected for a project.

Understanding the Calculations for Steel Beams

Steel beam calculations, crucial in construction and engineering, are underpinned by elementary mathematical principles. From the outset, these computations help ascertain the permissible load a beam can endure before deformation or failure starts, involving equations that determine bending moment (M), shear force (V), and other critical factors such as deflection.

Consider, for example, the calculations for bending moment (M) that incorporate the formula:

- M = F * d.

Here, F symbolizes the exerted force, and d constitutes the distance from the point of application of the force to the point where the bending moment is detected.

In the case of shear force (V), the formula utilized is

- V = F,

where F represents the aggregate force perpendicular to the beam. Engineers also ascertain the moment of inertia during these variations of calculations – a characteristic of the beam’s cross-sectional shape that illustrates its resistance to bending and deflection.

Grasping these concepts and implementing these calculations is fundamental in ensuring the efficient, safe, and effective implementation of steel beams in diverse scales of construction.

Types of Steel Beams and Their Calculations

A Closer Look at Various Types of Steel Beams

Within the realm of construction, several types of steel beams come into play, each boasting its unique properties and applications. The prominent ones include I-beams, H-beams, T-beams, and C-beams.

I-beams

Identified by an I or H-shaped cross-section, an I-beam (also referred to as an H-beam, wide flange beam or W-beam) has a ‘web’ or vertical element, and a ‘flange,’ the horizontal element. Primarily due to their ability to withstand varied loads, these beams have become a staple in residential building constructions. It’s worth noting that the broader the flange and the taller the web, the more robust the beam.

H-beams

Distinguished from I-beams by their wider flanges, H-beams are lighter in weight, rendering them a more economical choice for specific structures. For instance, in projects such as concert halls or bridges that necessitate long spans, H-beams are typically favoured to reduce weight and cost implications.

T-beams

T-beams, as their name suggests, sport a T-shape and come into the picture when considerable load-bearing capacity is required. The flange, formed by the top of the T-beam, can endure compressive stresses, while the vertical part, or web, can withstand shear stresses.

C-beams

Finally, C-beams or C-channel beams, are recognized by their letter C shape. They are typically employed in smaller-scale construction tasks and ideally suited for scenarios that necessitate a balance between core strength and lightness.

An Introduction to Steel Beam Calculations

When drafting the perfect design for a building or structure, one must consider several key variables. These include the desired span of the beam, the load it is expected to hold, and the weight of the beam itself. Therefore, the static design of steel beams requires fundamental knowledge in Material Mechanics and Structural Mechanics.

One of the most critical calculations in this process revolves around the Moment of Inertia. This property defines the capacity of the beam to resist bending or warping under stress. Simply put, the higher the Moment of Inertia, the lesser the beam will bend upon applying load.

For those dealing with I-beams with a rectangular cross-section, they can derive the Moment of Inertia using the formula:

- I = b*h^3/12,

- where ‘b’ represents the width of the flange and ‘h’ stands for the height of the web.

Another concept of prime importance is the Shear Force, its the force vector component that remains parallel to the cross section of the beam. This force plays a crucial role while conceiving the designs of structures.

The last crucial calculation involves the Modulus of Elasticity, a factor that measures the flexibility of the steel beam in question. It is computed using the formula E = stress/strain.

As emphasized, all these calculations need precision and clarity, as any errors could potentially lead to disastrous structural failures.

The Process of Steel Beam Calculations

A Closer Look At Load Types for Steel Beam Calculations

Initiating the steel beam calculations, it’s paramount to first determine the different kinds of loads the beam will typically bear. This gives us an accurate perception of the extent of force a certain steel beam can withstand. We can broadly categorize these loads into three areas: dead loads, live loads, and dynamic loads.

Dead loads refer to the static, unvarying weight that the beam constantly supports; this could be the weight of the beam itself or other permanent structures it upholds. Conversely, live loads represent temporary and changeable weights like the presence of people, furniture, or even accumulating snow on a roof. Lastly, dynamic loads pertain to sudden, often unpredictable forces acting on the structure, including the effects of wind or earthquakes.

Calculating Beam Reactions

Once the type and amount of load are known, the next step entails calculating the reactions at the supports, known as ‘support reactions’. Support reactions are the forces at the support points of the beam, which balance out the applied loads and keep the beam stable. To calculate these reactions, the principles of statics are applied, which dictate that the sum of vertical forces, horizontal forces, and moments (turning effects) should all be zero. From these three equations, the reaction forces can be determined.

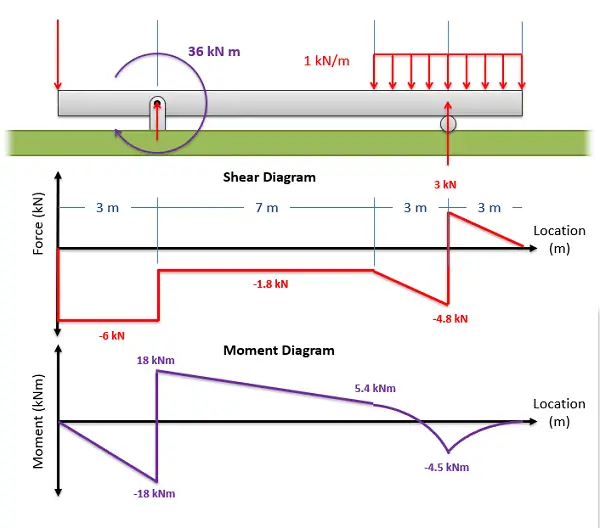

Bending Moment Diagrams

A critical aspect of steel beam calculations is the use of bending moments. The bending moment at any location along the beam can be calculated by subtracting the sum of forces to the left of a point from the sum of forces to the right. The result can then be graphed to create the bending moment diagram.

This diagram provides valuable information on the maximum bending moment the beam will experience, which ultimately determines the size and type of beam required. It is essential to know the maximum bending moment because it points out where the highest stress is likely to occur in the steel beam.

Calculating Beam Stresses

The next logical step is to calculate the stresses in the beam. This can be done by using the formula:

- Stress = M (bending moment) / S (section modulus).

The section modulus depends on the size of the beam and its shape, and it provides insights into the beam’s uniformity in bending stiffness and strength. It’s necessary to ensure that the calculated stress is lower than the allowed stress for the type of steel used, adding a factor of safety.

Walkthrough Examples

Take a steel beam that supports a uniformly distributed load from a concrete slab, for example. The dead load of the slab could be calculated based on the slab’s dimensions and material properties, while the live load might come from estimated use, such as office space (50 lbs/ft²) or residential use (40 lbs/ft²).

Support reactions and bending moments would be calculated following the principles of statics and using the method of sections. From this, the bending moment diagram could be drawn, and the section modulus could be chosen from a table of standard steel shapes. Finally, the stress in the beam could be found and compared to the allowable stress.

In Summary

Once you grasp these steps, conducting accurate steel beam calculations and ensuring safety will not be a difficult task. This will also aid you in selecting the most suitable beams for your various projects.

The Importance and Relevance of Accurate Beam Calculations

Understanding the Importance of Steel Beam Calculations

Designing a new project, be it a towering skyscraper or a compact residence, involves intricate calculations carried out by architects and engineers. Among these important calculations are steel beam computations.

These decisions specify the perfect size, shape, and positioning for each steel beam within the structure. It’s worthwhile to note that the calculations are based on advanced mathematics that consider factors like the load-bearing capacity, steel stiffness, possible environmental effects, and even the potential of seismic activities.

Repercussions of Inaccurate Steel Beam Calculations

Errors in these calculations can lead to dire, even fatal consequences. For instance, a mistake made during the construction of the Hyatt Regency Hotel in Kansas City, Missouri in 1981 is a tragic example of what happens when steel beam calculations go awry. In this case, the bridge walkways of the hotel collapsed, causing the death of 114 people due to a critical engineering error in the design of the steel rods.

Historic Instances of Inadequate Beam Calculations

A better-known instance is the collapse of the Tacoma Narrows Bridge, which involved inaccurate calculations and lack of awareness on the dynamic characteristics of the bridge frame. This led to a catastrophic failure, visible in a dramatic collapse that took place just a few months after the bridge was opened in 1940. It wasn’t a steel beam miscalculation per se, but it illustrates the importance of accurate planning and understanding the forces at play in a structure’s design.

The Complexity of Steel Beam Calculations

Accurate calculation becomes even more complex when steel beams have to be adjusted or augmented in an existing structure. This was the situation in the Aon Center in Chicago, originally named the Standard Oil Building. After its completion in 1973, it was found that the marble exterior was cracking and buckling, posing a risk to the public.

The building’s exterior was replaced with granite, vastly increasing the weight load on the steel frame. The architects and engineers were required to recalculate beam loads, an impressive undertaking, given there was no way to undo the original construction.

The Value of Accuracy in Steel Beam Assessments

Moving the lens to various high-profile scenarios helps to emphasize the crucial role of precise calculations in both architectural and structural engineering tasks. It is a note to all professionals in the field that they need to dedicate detailed attention to core factors such as load, weight, force, and the environment during the determination of steel beam specifications and placement. The safety of the public is directly tied to the accuracy of these calculations, highlighting their importance.

Tools and Software for Steel Beam Calculations

Exploring Technological Tools for Steel Beam Calculations

Moving forward, the article discusses the significant impact of modern technology in enhancing the accuracy and efficiency of steel beam calculations. Today, engineers have access to an array of innovative software tools like AutoCAD, SolidWorks, Autodesk Revit, Tekla Structures, and BeamChek. Each of these tools offers unique features tailored to specific calculation needs, making it easier for engineers to handle the often complex process of design and calculation.

AutoCAD: The Premier Drafting Software Tool

AutoCAD is one of the premier drafting software tools on the market. Known for its versatility and accessibility, AutoCAD supports the design process by providing a platform that facilitates the drafting of blueprints and sketches, reducing hand calculations and error margins. It offers a range of functionality for structural engineers, including detailed steel beam calculations and sketching, architectural modeling, and 3D printing.

SolidWorks: Engineering Design and Analysis Tool

SolidWorks is a CAD (Computer-Aided Design) software designed to provide engineers, designers, and other technology-based roles with the ability to perform stress analysis on a structure or a component. Its feature of simulating real-world conditions allows engineers to assess the performance of their steel beams under different loading conditions, offering an extra layer of analysis that can be invaluable in ensuring safety and efficiency.

Autodesk Revit: Advanced, Comprehensive Software for Structural Engineering

Autodesk Revit’s engineering design software focuses on building information modeling (BIM), allowing engineers to visualize and simulate their designs. Revit’s integrated tools let users create intelligent models, offering insights into constructability and performance. In terms of steel beam calculation, it provides a detailed analysis of the load-bearing capacities and stress points of the beams.

Tekla Structures: Detailed and Accurate Modeling Software

As a modeling software designed for detailing and fabricating structural steel elements, Tekla Structures allows engineers to create 3D models that accurately represent how structures will behave in real-life situations. It can automatically carry out calculations for weight, area, and center of gravity of steel composite beams, providing a well-rounded solution to steel beam calculations.

BeamChek: A Tool for Residential Structural Analysis

BeamChek is a software tool aimed towards residential structural design. It encompasses wood, steel, and engineered beams, enabling simple and quick analysis of beam sizes, loads, and spans. It’s excellent for smaller projects or those in the early conceptual stages.

Comparisons between these technologies suggest that the choice of software tool depends largely on the specific job at hand. For example, SolidWorks or Autodesk Revit leans towards complex designs and comprehensive analysis, while BeamChek is more suited for simpler, residential projects. Therefore, understanding each tool’s capabilities and strengths is key to using the right software for specific steel beam calculations and projects.

Although gaining a thorough understanding of steel beam calculations might not turn readers into certified civil engineers, it does elevate our general knowledge of the world we inhabit. It affords us a sense of appreciation for the intricate calculations that go into creating sturdy, lasting structures – and the realization of the critical nature of accuracy in these calculations. The article introduced the various types of steel beams and explained their calculations in an accessible language.

Ultimately, we cannot overlook the significance of technological tools, as they not only simplify the work process for engineers but also make it more precise, ensuring the longevity of structures. So the next time you find yourself marveling at a skyscraper or a bridge, you’ll have a glimpse into the intricate math and engineering that formed its backbone.