What is underfill in welding?

Underfill in Welding is an external welding defect that occurs on weld face side. Underfill in welding is a condition where the weld metal does not completely fill the space (Weld groove) between the two pieces of metal being joined.

This can happen for a variety of reasons, including improper technique, incorrect wire size, or incorrect gas mixture. Underfill can cause problems with the strength and integrity of the weld, so it is important to avoid it.

There are a few different ways to avoid underfill. First, make sure you are using the proper welding technique.

Second, use the correct wire size for your welder and make sure the gas mixture is correct. Third, practice makes perfect! The more you weld, the better you make sure at avoiding underfill.

Underfill Weld Causes: What causes Underfill in welding?

There are many causes of underfill in welding, but the most common are:

- Poor metal preparation,

- Incorrect welding parameters,

- Welding with high travel speed

- Incorrect electrode angle and

- Surface Contamination

- High welding heat input.

Poor metal preparation is often the cause of underfill because it can lead to a lack of fusion between the filler metal and the base metal. This can be caused by not cleaning the base metal properly before welding or by using the wrong type of filler metal.

Incorrect welding parameters can also cause underfill. This is usually due to using too much heat or too little heat when welding. Using high travel speed will provide insufficient weld metal in the groove, causing underfilling the weld groove.

Similarly, welding with incorrect torch angle can cause weld metal to disperse or accumulate on one side of groove, causing underfill on other side of the weld spacing.

Contamination is another common cause of underfill. This can be caused by dirt, rust, oil, or other contaminants on the base metal that can prevent weld to fuse properly with the base metal.

How to prevent underfill in Welding?

Welding is a process that joins two materials, usually metals, by heating them to the point of melting and using a filler material to add metal to the weld spacing or groove area.

Underfill is a common problem in welding, and it occurs when the weld pool doesn’t completely fill the joint. This can happen for a number of reasons, but the most common cause is improper welding technique.

There are a few things you can do to prevent underfill:

- – Use the proper welding technique. This means keeping the electrode at the correct angle and maintaining a steady speed as you move it along the joint.

- – Use the right size electrode. If the electrode is too small, it won’t be able to create enough heat to properly melt the metal.

- – Use weaving technique when filling large weld groove.

- – Control your welding speed. Ensure you are using right travel speed that is sufficiently filling the welding groove.

- – Use correct welding parameters as per welding procedure. Too low welding current or wire feed speed will not be able to provide sufficient weld metal to fill the welding joint.

Remedies of Underfill in Welding

Welding is a process of joining two materials, usually metals or thermoplastics, by causing coalescence.

This is typically done by melting the workpieces and adding a filler material to form a pool of molten material (weld pool) that cools to form a joint that is usually stronger than the base material.

However, if the weld pool does not completely fill the space between the two materials being joined, it is known as an Underfill Defect in Welding.

Underfill can be caused by several factors, including incorrect torch angle, incorrect welding speed, or insufficient filler material. It can also be caused by contamination of the weld pool with dirt or impurities.

Underfill can be remedied by increasing the amount of filler material, changing the torch angle, or increasing the welding speed.

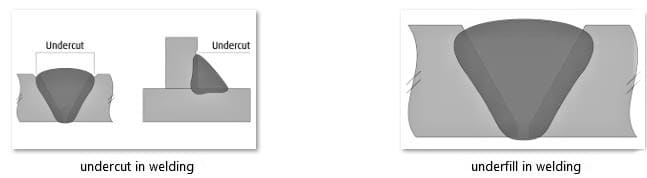

Weld Underfill vs. Undercut

Weld undercut is a condition that can occur when welding, resulting in a groove or depression in the weld at the weld toe area in a fillet weld or groove weld.

This can be caused by several factors, including incorrect welding technique, incorrect torch angle, or too much heat being applied to the weld. If not corrected, weld undercut can weaken the joint and cause it to fail.

In the below example, you can notice the welding underfill vs Undercut comparison.

Weld underfill is a condition that can occur when welding, resulting in an incomplete weld or “cold lap.” This leads to insufficient or inadequate weld metal size (throat size a/s).

This can be caused by several factors, including incorrect welding technique, incorrect torch angle, or too much heat being applied to the weld.

If not corrected, weld underfill can weaken the joint and cause it to fail.

Q: What is welding underfill?

Q: What causes welding underfill?

Q: How is welding underfill repaired?

Q: What are the consequences of welding underfill?

Material Welding is run by highly experienced welding engineers, welding trainers & ASNT NDT Level III bloggers.

We strive to provide most accurate and practical knowledge in welding, metallurgy, NDT and Engineering domains.