Effective size of Groove Welds

The maximum effective length of any groove weld, regardless of its orientation, is determined by the width of the part being joined, perpendicular to the direction of tensile or compressive stress. For groove welds transmitting shear, the effective length is the specified length.

The effective size of a groove weld refers to the dimensions of the weld that contribute to its strength and load-carrying capacity. It is important to determine the effective size of a groove weld for design and analysis purposes.

The effective size of a groove weld is typically defined by two key dimensions:

- Depth of penetration.

- Throat size.

Throat Thickness (a): The throat thickness is the effective size of the weld in the direction perpendicular to the applied load. It represents the minimum distance from the face of the weld to the root of the joint. The throat thickness is a critical dimension as it determines the weld’s resistance to shear and tensile forces.

The effective size of a groove weld can be calculated based on the geometry and dimensions of the weld joint. The specific calculation methods may vary depending on the welding code or standard being followed. Welding codes such as the American Welding Society (AWS) D1.1 or the International Institute of Welding (IIW) recommendations provide guidelines and equations for determining the effective size of groove welds.

Effective size of CJP Groove Welds

For a CJP (Complete Joint Penetration) groove weld, the weld size is determined by the thickness of the thinner part being joined. The effective area for design calculations should not be increased for weld reinforcement.

CJP (Complete Joint Penetration) groove welds are a type of groove weld where the weld joint is fully penetrated, meaning that the weld metal completely fills the joint between the two pieces being welded. The effective size of CJP groove welds is determined by the throat thickness and the weld reinforcement.

- Throat Thickness (a): The throat thickness of a CJP groove weld is the effective size of the weld in the direction perpendicular to the applied load. It represents the minimum distance from the face of the weld to the root of the joint. The throat thickness is a critical dimension as it determines the weld’s resistance to shear and tensile forces. In CJP groove welds, the throat thickness is equal to the thickness of the thinner piece being joined.

- Weld Reinforcement: Weld reinforcement refers to the additional weld metal that extends beyond the surface of the joint. In CJP groove welds, the weld reinforcement is typically minimal or nonexistent since the joint is fully penetrated. The effective size of the weld is determined by the throat thickness, and the weld reinforcement does not contribute significantly to the weld’s strength or load-carrying capacity.

The effective size of CJP groove welds is primarily determined by the throat thickness, which is equal to the thickness of the thinner member being joined. It is important to consider these dimensions when designing and analyzing weld joints to ensure that they meet the required strength and performance criteria.

Effective size of PJP Groove Welds

PJP (Partial Joint Penetration) groove welds should be equal to or greater than the size specified in AWS D1.1 5.4.2.3(1) as shown below, unless the WPS (Welding Procedure Specification) is qualified as per the defined clause.

Table 10.7 of AWS D1.1 provides the sizes for T-, Y-, and K-connections in tubular construction.

Effective Area of Groove Welds

The effective area of a groove weld is calculated by multiplying the effective length by the effective weld size.

The effective area of a groove weld refers to the portion of the weld that contributes to the load-carrying capacity and strength of the joint. It is an important parameter for design and analysis purposes in structural engineering.

The effective area of a groove weld is typically determined by two key dimensions:

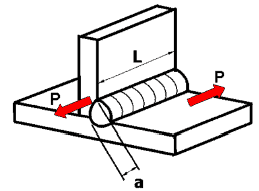

- Throat Thickness (a): The throat thickness is the minimum distance from the face of the weld to the root of the joint. In a groove weld, the throat thickness represents the effective size of the weld in the direction perpendicular to the applied load. It is a critical dimension as it influences the weld’s resistance to shear and tensile forces. The effective area of the groove weld is calculated by multiplying the throat thickness by the length of the weld.

- Length of Weld (L): The length of the weld refers to the linear distance along the joint where the weld is present. It is an important factor in determining the effective area of the groove weld. The effective area is calculated by multiplying the throat thickness by the length of the weld.

The formula to calculate the effective area of a groove weld is:

Effective Area = Throat Thickness (a) x Length of Weld (L)

It’s important to note that the effective area of a groove weld may differ from the actual area of the weld as specified on engineering drawings. The effective area represents the portion of the weld that contributes to the joint’s strength and load-carrying capacity.

Effective size of Fillet Welds

The effective size of fillet weld shall be a minimum of 25% of the leg dimension or four times the nominal size, whichever is greater. Effective length of straight fillet welds, which includes the overall length of the full-size fillet, including end returns. There is no reduction in effective length considered for design calculations due to the start or stop crater of the weld.

Effective length of curved fillet welds, which is measured along the centerline of the effective throat.

Minimum length of segments for intermittent fillet welds

The minimum length of segments for intermittent fillet welds is typically specified in welding codes and standards, such as the American Welding Society (AWS) D1.1 Structural Welding Code. The specific requirements may vary depending on the application, material, and design considerations.

As per AWS D1.1, the minimum length of segments for intermittent fillet welds, which shall be 1-1/2 inches [38 mm].

Maximum Effective Length

For end-loaded fillet welds lengths up to 100 times the leg dimension, the effective length can be taken as the actual length. For lengths between 100 and 300 times the weld size, the effective length is determined by multiplying the actual length by a reduction coefficient. When the length exceeds 300 times the leg size, the effective length is taken as 180 times the leg size.

Calculation of the effective throat for fillet welds

Section 4.2.6 outlines the calculation of the effective throat for fillet welds between parts meeting angles between 80° and 100°. The effective throat is the shortest distance from the joint root to the weld face of a 90° diagrammatic weld.

For acute angles between 60° and 80° and obtuse angles greater than 100°, the weld leg size required to provide the specified effective throat is calculated considering the geometry. For acute angles between 60° and 30°, the leg size is increased by the Z loss dimension.